It is possible to customize the working area of this model in any of the 3 axes, adapting it to your real production needs.

Example of manufacturing with special measures:

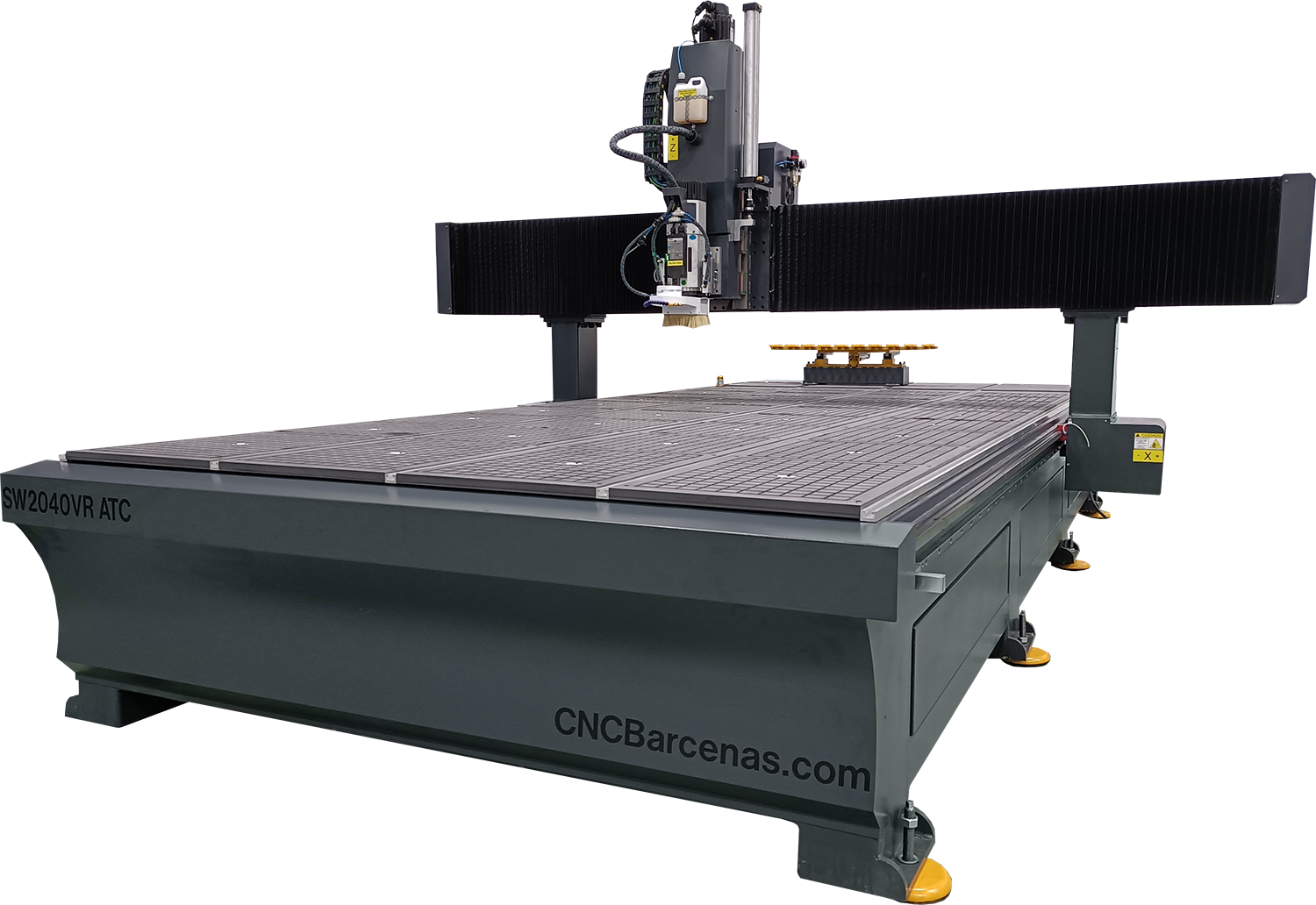

This model, custom made for a customer, has special Z height, created following his special needs in Z axis height with 500 mm, which allows milling large size materials, achieving a large total working volume. It has a working area of XYZ: 1300 X 2500 X 500 MM.